The solution is made possible through RFID technology. Radio Frequency Identification (RFID) technology allows information to be read wirelessly from a distance. RFID allows for multiple items to be read at one time at distances up to hundreds of feet, and does not require a direct line of site. Matrix Product Development used RFID technology to create the Wyze-Temp® system, and customized it to meet Alkar's needs. In this application, an RFID enabled sensor is attached to the product being cooked as it passes down the oven’s conveyor belt. It is specifically designed to withstand the extreme heat of the oven. From inside of the oven, it transmits the real time temperature information wirelessly for immediate feedback and analysis. If the temperature moves outside of specified variance parameters, an audible or visible signal/alarm is is activated.

Wyze-Temp® is incredibly valuable to Alkar for three reasons:

1. Raw material cost savings. The immediate and accurate feedback on temperature allows users of Alkar's equipment to monitor and adjust heat controls much more effectively than other equipment, which provides additional protection against thousands of pounds of food product being improperly cooked and potentially wasted.

2. Labor Costs. Labor costs are greatly reduced as employees no longer have to be responsible for the dutiful task of opening and closing the oven door to take readings throughout the day.

3.Regulatory Compliance. This Wyze-Temp® system also helps Alkar stay compliant to the many regulations of the U.S. Department of Agriculture which very closely monitors the inner workings of meat preparation and cooking. The Wyze-Temp® system helps ensure that nothing goes wrong during the cooking procedure which could lead to E-Coli or other sickening food-borne illnesses.

Alkar and Matrix Product Development first met in 2007 to discuss how to improve quality in Alkar's equipment. By 2009, Alkar was using Wyze-Temp® temperature sensors in their continuous-cooking ovens. Alkar relies on the Wyze-Temp® system to allow them to be successful in the food-processing industry where there is little margin for error. Matrix Product Development's successful implementation of the Wyze-Temp® system for Alkar opens the door for further expansion of this unique RFID application across a wide array of industries and market lines. Five other companies are now using the system for their continuous-cooking ovens which utilize a conveyor belt system, as well as many more which use it for batch ovens in which the food is relatively stationary.

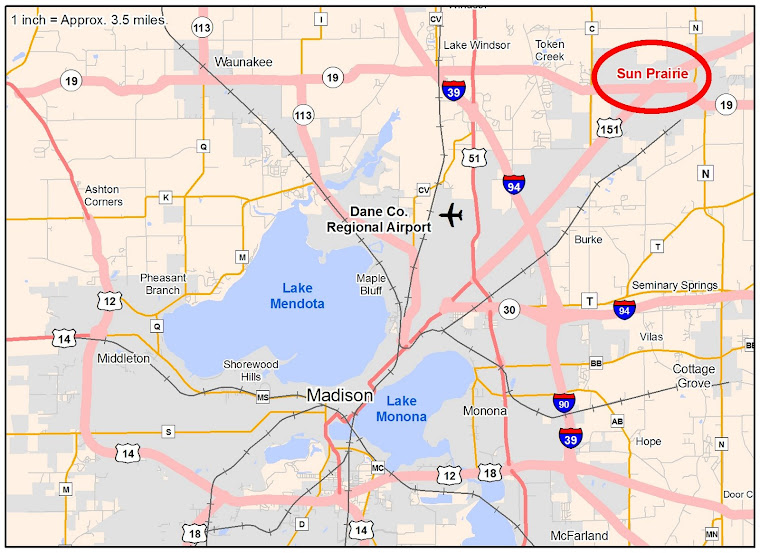

Matrix Product Development is a high-tech electronic design and product development firm based in Sun Prairie, Wisconsin in the Greater Madison area. For more information, click here, contact Matrix Product Development at 608-834-1661 or email info@matrixpd.com.

No comments:

Post a Comment